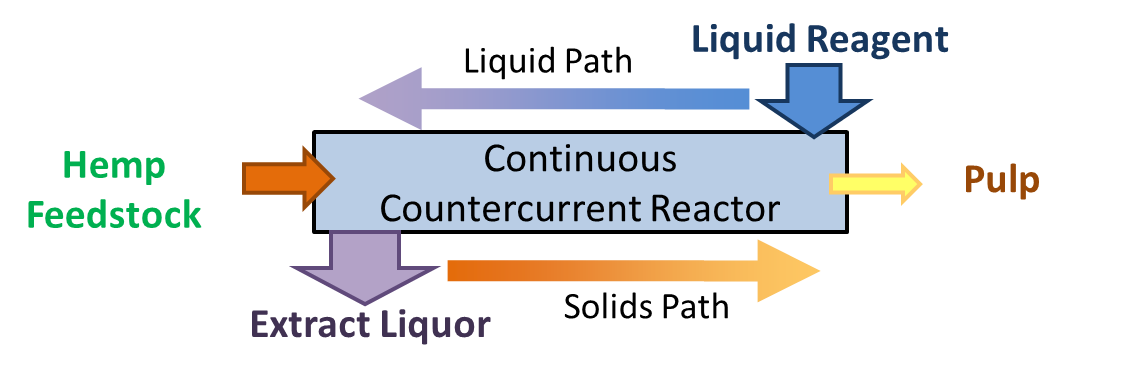

PureHemp has exclusive worldwide access to a highly disruptive technology that has many advantages over current biomass conversion technologies. Based on years of R&D and favorable results, PureHemp’s patented continuous countercurrent reactor (“CCR”) technology along with other in-line equipment rapidly converts hemp stalks and other biomass into raw materials to manufacture a wide variety of products. Countercurrent processing, where the solid hemp stalks move in the opposite direction of the liquid reagent, has proven to create highly effective reactions. Processing hemp in the CCR results in the production of pulp as one product, and the extract liquor is further refined into lignin and sugar co-products.

PureHemp’s CCR technology is very versatile, allowing different processing configurations for producing a wide variety of products.

1200 Pound per Day CCR Pilot Plant: After 12 years of developing proof of concept operating data, PureVision designed and built its first CCR in 2003, able to process 120 pounds (dry weight) of biomass per day. With a successful scale-up, the second CCR was developed in 2008, capable of processing 1,200 pounds per day. In 2014, hemp was processed in the CCR for the first time. Based on encouraging results generated during the past three-plus years, plans are underway to develop a small commercial-scale, 4-ton per day CCR, targeted to be developed in 2018 and go into operation during 2019, followed by a 40-ton per day CCR planned to go into production in 2021.

Employing the PureHemp CCR technology will add significant value to the emerging hemp refining industry by utilizing hemp stalks for economical production of hemp-based products. In addition to traditional fiber and seed products, there are novel products that can be produced from hemp using the PureHemp CCR technology, specifically pulp, lignin, sugars and extracts.

The U.S. trend to legalize the cultivation of industrial hemp is creating many new business opportunities for farmers, end product manufacturers, entrepreneurs and investors. Perhaps the greatest emerging market driver is the growing demand for hemp-based products in the U.S., ranging from nutraceuticals, body care products, food supplements, sweeteners, specialty chemicals, paper and tissues, plastics, lightweight composites, just to name a few. With the growing demand for hemp-based products, the hemp value chain, from field to end products, coincides perfectly with the production, branding and marketing opportunities being pursued by PureHemp.